Advanced Manufacturing

MBP is an established prototyping partner amongst OEMs throughout industry, continuing to gain acclaim for its abilities to rapidly create highly detailed production quality parts. Through the wealth of knowledge in prototyping technologies to pioneering methods of producing parts, MBP is highly regarded and trusted within many of the world’s leading automotive brands.

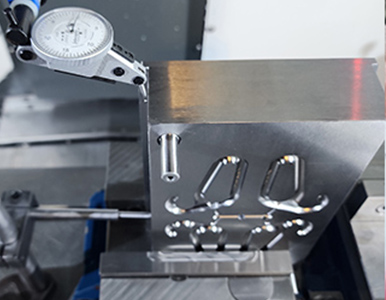

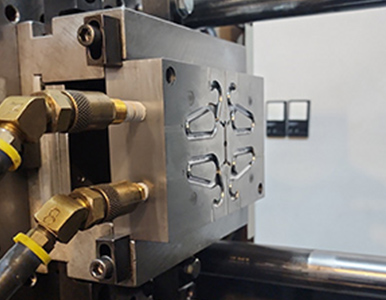

MBP offer tooling capabilities that support the rapid manufacture of pre-series parts, through to low volume and full production tooling. Throughout any tooling process, customers receive expert knowledge to advise on the best tooling routes and guidance on any existing tooling modification work. As tooling innovators, MBP also deliver new to industry techniques to keep customers ahead of the market.

We help engineers, who are either frustrated with the lack of technical support, or currently served by suppliers who do not understand the quality and timing expectations of the niche vehicle and low volume sector. We have found customers typically turn to us when either:

Post Processing at MBP: we have a well-equipped finishing workshop in-house and team with decades of experience between them.

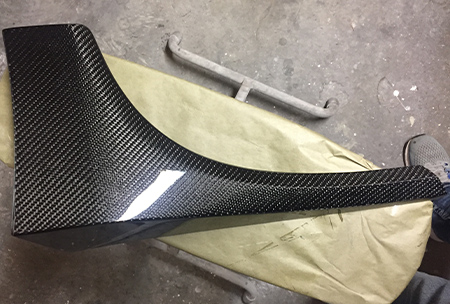

Carbon Fiber

Carbon fiber is an art form. Here at MBP we take our time and build beautiful parts. Our customers expect straight lines and crisp parts as do we.

Our level of quality is shown in all the parts we do. We use pre-preg carbon fiber and have an oven large enough for pretty much any sized part. We work with fiberglass and carbon molds, CNC aluminum molds and even 3d printed molds.

Types of Manufacturing

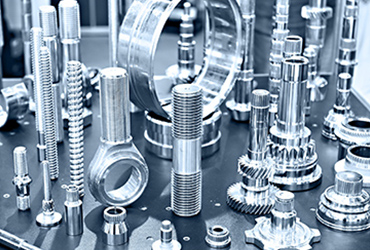

Whether it is a production part or tooling made out of aluminum, stainless steel or titanium, we've got you covered.

Pre-preg carbon fiber parts built to the highest quality to create a beautful part. Our level of quality usually exceeds anything else on the market.

We can make parts out of a variety of materials for prototyping or production. 3d printing can be a good short run option or move up to injection molding for a long term production run.